-

Envie-nos um e-mail

sale@lscmagnetics.com -

Número de contato

+86 -13559234186

Envie-nos um e-mail

sale@lscmagnetics.com

Número de contato

+86 -13559234186

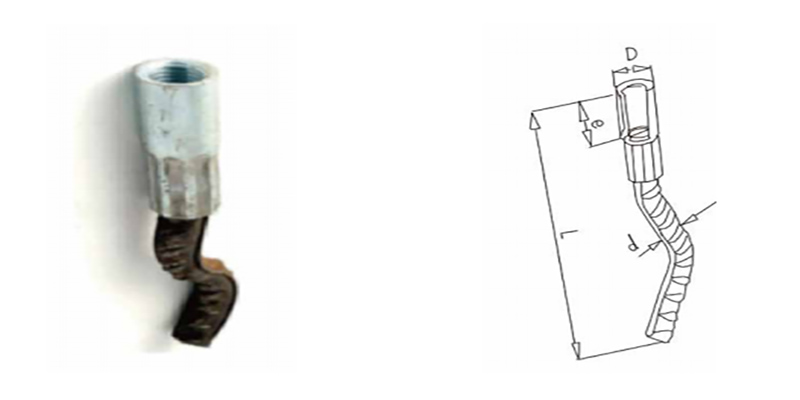

A âncora de cauda ondulada curta é uma solução de içamento compacta e de alta resistência para componentes pré-fabricados de concreto. Sua cauda de barra de reforço em formato de onda garante distribuição uniforme da carga, previne fissuras no concreto e permite uma conexão segura a buchas roscadas ou insertos de içamento, possibilitando uma operação segura e eficiente. A capacidade de carga de trabalho segura da âncora varia de 0,5 a 8,0 toneladas, e o tamanho, a altura e o diâmetro da rosca podem ser personalizados para atender aos requisitos de diversos projetos de concreto pré-fabricado, garantindo içamento e instalação seguros.

Item nº :

Wavy Tail Anchor(short Type)Pedido (quantidade mínima) :

500Origem do Produto :

chinaTempo de espera :

7-10daysÂncora de cauda ondulada (tipo curto)

O que é uma âncora de cauda curta?

Uma âncora de cauda ondulada curta é um tipo especial de âncora de cauda ondulada, assim chamada devido à sua cauda curta. Ela pode ser conectada diretamente a uma bucha roscada. É projetada especificamente para fornecer um ponto de içamento ou uma conexão roscada segura para componentes pré-moldados de concreto. O design ondulado da barra de reforço aumenta a área de contato na direção da carga, garantindo uma distribuição uniforme da carga e evitando que a âncora seja arrancada ou que o concreto trinque. Ela é pré-embutida no componente de concreto e usada posteriormente para:

Elevação: Como ponto de apoio para desmoldagem, inversão, transporte e instalação de componentes.

Conexão: Para uma conexão confiável com outros componentes ou com a estrutura principal.

Ancoragem: Para resistir às forças de tração e cisalhamento geradas por cargas de vento, ações sísmicas, etc.

Comparado comÂncora de cauda ondulada (tipo longo)As âncoras de cauda de onda curta praticamente não possuem seção reta entre a barra de reforço e a luva roscada, resultando em uma estrutura mais compacta, mantendo a resistência. Elas são comumente utilizadas em componentes pré-fabricados onde são necessários içamento, ancoragem ou suporte temporário confiáveis durante o transporte e a instalação.

Princípio de funcionamento das âncoras de cauda de ondas curtas:

As âncoras de cauda ondulada curta distribuem uniformemente a carga de elevação de componentes pré-fabricados de concreto para o interior do componente através de sua cauda de aço em formato de onda, evitando que o componente seja arrancado e sofra fissuras. Elas podem ser conectadas com segurança a soquetes roscados ou anéis de elevação, proporcionando um ponto de elevação estável. A carga de trabalho segura (SWL) adequada, a compatibilidade da rosca e a conformidade com as normas relevantes garantem operações de elevação seguras e eficientes. Durante o ensaio de tração, utilize sempre um fator de segurança de pelo menos três.

Especificações da âncora de popa para ondas curtas

| Código | Slze | SWL | L | D | d | e |

| KGS | (mm) | (mm) | (mm) | (mm) | ||

| LSC 330112108 | Rd12 | 500 | 108 | 16 | 8 | 22 |

| LSC 330116167 | Rd16 | 1200 | 167 | 21 | 12 | 27 |

| LSC 330120187 | Rd20 | 2000 | 187 | 27 | 14 | 35 |

| LSC 330124240 | Rd24 | 2500 | 240 | 31 | 16 | 43 |

| LSC 330130300 | Rd30 | 4000 | 300 | 40 | 20 | 56 |

| LSC 330136380 | Rd36 | 6300 | 380 | 48 | 25 | 69 |

| LSC 330142450 | Rd42 | 8000 | 450 | 54 | 28 | 80 |

| Outros comprimentos e roscas métricas diferentes estão disponíveis. | ||||||

| Sob consulta, a Safety Factory tem uma proporção de 4:1. | ||||||

| Vantagens | Incorporação central |

| Eficiência de ancoragem | Profundidade de ancoragem curta e alta capacidade de carga: A superfície ondulada forma um forte encaixe mecânico tridimensional no concreto, proporcionando resistência à extração muito superior à das hastes retas tradicionais ou das âncoras de gancho do mesmo tamanho. |

| Adaptabilidade espacial | Adequado para componentes de paredes finas: Seu tamanho reduzido permite sua utilização em componentes de paredes finas com espaço limitado, como lajes mistas e painéis de parede pré-fabricados, sem a necessidade de reforço local para ancoragem, otimizando assim o projeto. |

| Desempenho sob estresse | Resistência sísmica e à fadiga superior: As estruturas onduladas podem dispersar eficazmente a tensão dinâmica, evitar a concentração de tensão e apresentar um desempenho mais estável sob carregamento cíclico. |

| Flexibilidade de design | Liberando a liberdade de design: fornecendo a arquitetos e engenheiros soluções de conexão confiáveis e perfeitas para projetos de componentes pré-fabricados leves e compactos. |

| Eficiência econômica geral | Otimizar os custos do ciclo de vida: Embora o custo por unidade possa ser ligeiramente maior, isso pode gerar economia no uso de concreto, simplificar a construção e melhorar a segurança a longo prazo, resultando em benefícios gerais significativos. |

Observações importantes:

A carga de trabalho SWL deve atender aos requisitos de uso.

Os tópicos devem atender aos requisitos de uso.

Deve cumprir as normas aplicáveis.

Os ensaios de limite de tração devem utilizar um fator de segurança de pelo menos 3.

Aplicações típicas:

Painéis pré-fabricados de concreto armado com isolamento térmico para paredes externas: Como conectores, seu tamanho compacto ajuda a reduzir as pontes térmicas, enquanto a alta resistência garante a segurança.

Grandes lajes alveolares protendidas/lajes mistas: Ideais para içamento e ancoragem posterior.

Sistemas de fixação traseira em concreto pré-moldado para fachadas cortina suspensas a seco: Proporcionam alta resistência à tração em espessuras limitadas.

Lajes pré-fabricadas para varandas, painéis de ar condicionado e componentes decorativos: atendem aos requisitos de ancoragem de componentes de paredes finas com formatos irregulares.

Fundações para equipamentos e instalação rápida: Utilizadas para equipamentos de sala de máquinas que requerem fundações pré-embutidas.

Por que nos escolher?

(1) Mais de 15 anos de experiência na fabricação e comercialização de sistemas de concreto pré-moldado.

(2) Cumprir os rigorosos requisitos técnicos e atender à demanda do mercado por segurança humana. (Elementos pré-fabricados de concreto podem ser içados diversas vezes após a concretagem e durante o armazenamento e a instalação - ao utilizar este sistema, projetistas e gerentes de equipe podem garantir que cada içamento seja feito com segurança e rapidez. Sem um sistema projetado e coordenado, pode ocorrer quebra de material em algum ponto durante a produção/entrega.

(3)Os produtos da LSC são aprimorados por meio de inspeções de controle de qualidade na fábrica durante a produção. Cada pedido pode ser testado quanto à tensão, se necessário.

(4) Capacidade OEM/ODM: A LSC tem mais de 10 anos de experiência em produtos OEM/ODM e mais de 150 fábricas cooperativas, podemos fornecer preços competitivos e qualidade estável.

ETIQUETAS :