-

Envie-nos um e-mail

sale@lscmagnetics.com -

Número de contato

+86 -13559234186

Envie-nos um e-mail

sale@lscmagnetics.com

Número de contato

+86 -13559234186

A comprehensive analysis of shutter magnets

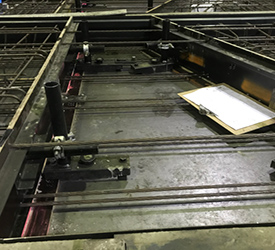

Feb 04, 2026In the precast concrete industry, traditional methods of securing formwork are not only time-consuming and labor-intensive but can also damage expensive steel casting beds. Is there an efficient, non-destructive solution? The answer is the shutter magnet. This revolutionary tool is transforming formwork fixation, significantly accelerating production cycles.

What is a Shutter Magnet?

A shutter magnet, also known as a magnetic box or box magnet, is a standard tool used to securely fasten formwork, side rails, and other components to steel casting beds in the precast concrete industry. Its core consists of a robust steel housing enclosing a high-performance neodymium magnet array. Unlike older methods requiring welding or drilling, it enables non-destructive, powerful magnetic attachment, protecting the work surface and allowing for rapid adjustment and release.

Understanding the Working Principle: The Key to Success

1. Basic Principle:

Shutter magnets function as an on/off switch for magnetic force. When activated, the internal magnet array engages, creating a powerful pull directly onto the clean steel surface. This pure magnetic hold requires no bolts, welding, or mechanical locks.

2. The Critical Need for Direct Contact:

Maximum holding force is achieved only with complete, direct contact between the magnet's base and the steel bed. Any contaminant—concrete residue, rust, paint, or debris—acts as a gap. Unlike a bolted connection, magnetic force cannot "clamp through" such obstacles; even minor gaps drastically reduce performance.

3. How Air Gaps Defeat the Magnet:

The magnetic force diminishes exponentially with distance. A gap of just 1-2 mm can reduce effective holding force by 50% or more. This is why a magnet rated for 1800 kg may fail in the field. Vibration can worsen these gaps, leading to dangerous "creep" or sudden displacement of the formwork.

Six-Step Installation Guide for Secure Fixation

1. Surface Preparation (Most Critical Step): Thoroughly clean both the magnet base and the steel bed. Remove all dust, oil, grease, and hardened concrete debris. This ensures metal-to-metal contact.

2. Formwork Placement: Position all side rails, stop ends, and other formwork components accurately on the bed according to the shop drawings.

3. Magnet Placement & Adapter Use: Place the shutter magnet against the formwork. If fixing to non-ferrous materials (e.g., timber, aluminum), first attach the appropriate non-magnetic adapter to the magnet's mounting points.

4. Activation & Locking: Firmly press the activation handle or lever. You should hear/feel a solid "clunk," indicating the internal magnets are fully engaged and gaps are eliminated. Always perform a **manual tug-test** to confirm a secure lock.

5. Pouring & Curing: Proceed with concrete placement and vibration. The magnet's design ensures stability against standard construction vibrations.

6. Safe Deactivation & Removal: After the concrete has cured, use the dedicated release tool (lever) to disengage the magnetic field. Never pry the magnet off. Clean the magnet immediately after removal.

Avoiding Common and Costly Installation Errors

Improper installation can lead to formwork blow-outs, dimensional inaccuracies, and serious safety incidents. The most frequent errors stem from neglecting the core principles above.

| Error Categories | Core risks | Key Corrective Actions |

| Inadequate cleaning | Adsorption capacity is severely insufficient, template displacement occurs. | Thoroughly clean both sides before installation to ensure no particulate oil or dirt remains. |

| Inefficient layout | Local deformation of template, out-of-tolerance dimensions of components | Based on mechanical calculations, the layout is optimized with increased density at the end corners to ensure sufficient quantity. |

| Incorrect operation sequence | Equipment damage, difficulty in adjustment, damage during disassembly | Strictly follow the sequence of "placement → fitting → activation" and use a special tool to release. |

| Neglecting maintenance and inspection | Sudden failure poses significant safety risks. | Regularly inspect the base plate for wear and tear and mechanical parts, and test the magnetic force. |

| Insufficient safety awareness | Pinching injury, being struck by an object | Wear protective gloves and verify the security of the lock after locking. |

Core Principle to Remember:

The reliability of a shutter magnet depends not just on its powerful magnetic rating, but on absolutely clean contact surfaces, a calculated layout based on concrete pressure, and strict adherence to the correct operating procedure. Avoiding these common mistakes is essential for safety, efficiency, and perfect precast product quality.