-

Envie-nos um e-mail

sale@lscmagnetics.com -

Número de contato

+86 -13559234186

Envie-nos um e-mail

sale@lscmagnetics.com

Número de contato

+86 -13559234186

Removedor de ferro totalmente automático: o "guardião invisível" na produção química

Aug 28, 2025Com o avanço contínuo da ciência e da tecnologia e o desenvolvimento da industrialização, a produção química tornou-se uma indústria indispensável e importante na sociedade moderna. Durante a produção química, manter um ambiente de produção limpo e seguro é particularmente importante. No entanto, a presença de ferro metálico frequentemente tem um impacto negativo no processo de produção. Para resolver esse problema, removedores de ferro totalmente automáticos surgiram como um equipamento essencial na produção química.

Primeiro, vamos discutir o princípio de funcionamento de um removedor de ferro totalmente automático.

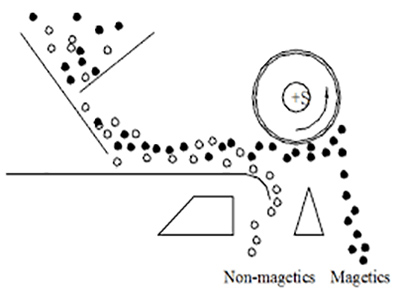

Um removedor de ferro totalmente automático utiliza uma fonte magnética de alta potência (como um ímã permanente ou uma bobina eletromagnética) para gerar um campo magnético, atraindo automaticamente as impurezas ferromagnéticas do material. Suas principais vantagens são:

Operação contínua: Não é necessário tempo de inatividade para limpeza, pois os mecanismos automáticos de raspagem e remoção de ferro garantem uma operação ininterrupta.

Identificação inteligente: combinando sensores de metal e um sistema de controle PLC, ele detecta e separa com precisão impurezas ferrosas.

Alta adaptabilidade: adequado para uma variedade de formas de materiais, incluindo pós, grânulos e líquidos, e apresentando resistência à corrosão e a altas temperaturas, atende às demandas de ambientes químicos especializados.

Por que os removedores de ferro totalmente automáticos desempenham papéis tão importantes na produção química? A razão fundamental é esta: impurezas de ferro em matérias-primas químicas podem causar vários problemas:

Reações catalíticas colaterais: íons de ferro podem catalisar reações químicas indesejadas, reduzindo a pureza do produto.

Desgaste do equipamento: limalhas de ferro duras aceleram o desgaste de equipamentos como bombas, tubulações e reatores, aumentando os custos de manutenção.

Contaminação do produto: especialmente na indústria química fina (como produtos químicos de nível eletrônico e intermediários farmacêuticos), traços de impurezas de ferro podem fazer com que um produto seja descartado.

Riscos de segurança: O atrito entre partículas de ferro e equipamentos pode gerar faíscas, potencialmente causando acidentes em ambientes inflamáveis e explosivos.

Embora pareçam uma etapa menor no processo de produção, os removedores de ferro totalmente automáticos são cruciais para garantir a qualidade do produto, o controle de custos e a segurança da produção. Na indústria química cada vez mais competitiva de hoje, a inovação tecnológica que prioriza cada detalhe é crucial para aumentar a competitividade essencial de uma empresa. Isso se reflete nos seguintes aspectos:

1. Na produção de plástico e borracha, removedores de ferro totalmente automáticos removem impurezas de ferro das matérias-primas, prevenindo manchas e estrias pretas nos produtos acabados e melhorando a aparência e a pureza do produto. Eles também reduzem o desgaste em componentes de precisão, como parafusos e moldes, causado por limalhas de ferro, prolongando a vida útil do equipamento, reduzindo os custos de manutenção e protegendo os equipamentos de processamento. Além disso, eliminam faíscas geradas pelo atrito entre impurezas de ferro e equipamentos, reduzindo o risco de explosões e ignições. Isso é particularmente crucial na produção de polímeros inflamáveis, garantindo a segurança da produção.

2. Nas indústrias de pesticidas e revestimentos, removedores de ferro totalmente automáticos impedem que íons de ferro catalisem reações químicas indesejadas, prevenindo a degradação, descoloração, formação de película e diminuição da estabilidade dos pesticidas, garantindo assim o desempenho estável do produto. A remoção de impurezas de ferro reduz a interferência no desenvolvimento da cor dos pigmentos, garantindo cores vibrantes e consistentes em lotes de revestimentos e formulações de pesticidas. Isso ajuda os produtos a atender aos rigorosos padrões de teor de impurezas nos mercados nacional e internacional (como o REACH da UE), rompendo barreiras comerciais.

3. Em relação aos novos materiais de energia, ele pode controlar rigorosamente as impurezas ferromagnéticas nos materiais catódicos (como fosfato de ferro-lítio e materiais ternários), evitando o aumento da autodescarga da bateria, o aumento da resistência interna e a degradação da capacidade, melhorando assim a densidade energética e a vida útil da bateria. Também elimina o risco de curto-circuitos introduzidos por corpos estranhos metálicos magnéticos, melhorando significativamente a segurança da bateria e prevenindo a fuga térmica.

Suplemento:

👀Depois de entender a importância de um separador magnético, escolher o equipamento certo é crucial.

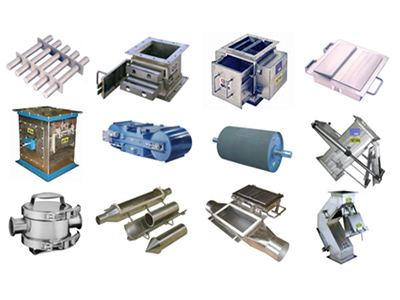

| Tipo | Como funciona | Características | Cenários aplicáveis |

| Removedor de ferro tipo gaveta | O material flui através da haste magnética permanente, os cavacos de ferro são atraídos por ela, e o cilindro puxa a haste magnética camada por camada para descarregar o ferro automaticamente. | A estrutura é relativamente simples e pode trabalhar continuamente sem interromper a alimentação ao descarregar o ferro. | Adequado para materiais em pó e granulares, como grânulos plásticos, matérias-primas alimentícias, etc. |

| Removedor de ferro rotativo | O ímã giratório gera um forte campo magnético, que atrai continuamente o ferro e remove automaticamente as impurezas através do raspador. | Possui grande capacidade de processamento e alto grau de automação, sendo adequado para linhas de produção contínuas. | Adequado para materiais em pó ou granulares com alta vazão e alto teor de ferro. |

| Removedor de ferro de oleoduto | Ele é diretamente integrado à tubulação e usa força magnética para absorver impurezas de ferro no material que flui na tubulação. | Fácil de instalar, boa vedação e economia de espaço. | Adequado para remoção de ferro em transporte pneumático ou tubulações de líquidos, como revestimentos, lamas, etc. |

💡 Recomendações de uso

Instalação adequada: normalmente instalada na entrada/saída ou na parte frontal/extremidade da linha de produção.

Manutenção regular: Limpe a barra magnética ou a superfície do ímã regularmente, de acordo com as instruções, para garantir o desempenho ideal da remoção do ferro. Verifique se há desgaste no equipamento.